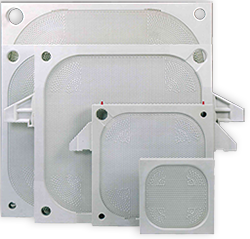

Filter plates

For liquid filtration applications that require optimal separation of liquids and solids, top-quality filter plates team up with the right filter press cloth to provide you with the improved means to achieve top performance. Like the accompanying filter press cloth, a filter plate is not one size fits all. The ideal design and construction depends on factors such as your filter press and the liquid filtration application. It is critical to keep your filter press in optimal working condition to maximize your filter press performance.

Let the filter media specialists at Markert collaborate with you on the ideal filter plate for your application. Our team’s combined years of expertise in optimal design and materials along with working with a wide range of industries and applications will help you get the best materials for your specific filtration system.

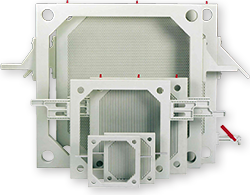

Filter Plate Design

The foundation of Markert’s design process is laid during our on-site evaluation of your filter press. During the onsite evaluation, our experts will examine the condition of your plates and determine the design, material, and construction necessary to achieve proper cake washing, air blowing, cake release, and better cake solids. When plates are in good working condition, the proper design will also maximize the performance of your filter press cloth getting you better filtrate clarity, improved dewatering, and faster cycle times.

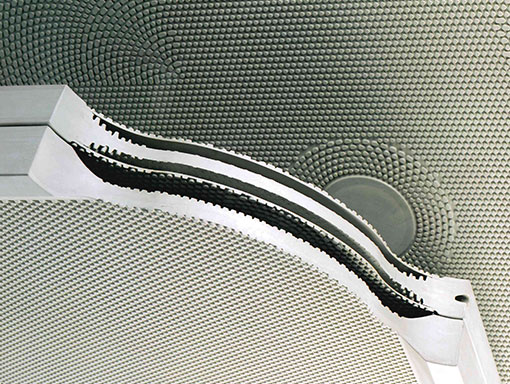

CGR/Gasketed Filter Plates

Gasketed plates are ideal for applications where potential wicking and leakage are unacceptable. Certain applications require a tighter and more precise fit which a gasketed plate style deliver.

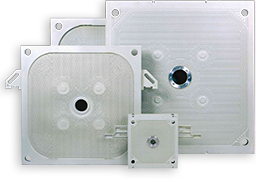

Plate & Frame Filter Plates

Plate & Frame designs utilize a Drape Over cloth and are ideal for polishing applications.

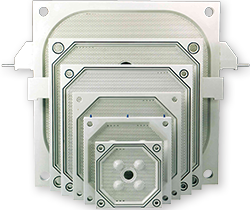

Membrane Filter Plates

A membrane filter plate is equipped with an inflatable squeeze system utilizing water or air. Designs include fixed or replaceable membranes in non-mixed pack or mixed pack configurations that alternate chamber and membrane plates.

Mixed pack configurations are commonly recommended for yielding improved cake solids, cake washing, and increasing cycle times for faster output and energy cost savings

Filter Plate Materials

The majority of filter plates consist of 100% virgin polypropylene. Homopolymer and Copolymer resins are both available depending on your operation conditions. Markert’s material inventory allows us to design your filter press plate with the correct materials based on your filtration requirements.

Filter Plate Sizes

No matter the size or specifications of your filter press, Markert can get you the the filter plates you need. Our filter press plates are available in all possible sizes. Common plate sizes are 470mm, 630mm, 800mm, 1000mm, 1200mm, 1500mm, 1.5m x 2m, and 2m x 2m.

More Filtration Products

Filter Hoses For Candle Filters

Our filter hoses, filter fabrics and support fabrics are supplied in seamless, sewn or welded variants. In this connection, we use textile, high-quality materials.

System: Candle filters

Areas of application: Chemical industry, alumina & food

Examples of use: Production of chlorine (chlorine electrolysis), production of sugar

Fluidisation funnels

Markert fluidisation funnels are used in silo vehicles for the even, trouble-free transport as well as for fast unloading of bulk goods.

System: Silo vehicles

Areas of application: Food, chemical industry, Mineral & Mining

Examples of use: Use in the loading and transport of bulk goods

Catching baskets for pelletising systems

Markert catching baskets are used in the pharmaceutical industry and are especially produced for catching the pellets (pharmaceutical active agents).

System: Fluid bed dryers

Areas of application: Food

Examples of use: Pharma tabletting

Filter discs

These filters are suitable above all for suspensions with a low solid content. We offer solutions in a wide variety of pore sizes.

System: Horizontal disc filters

Areas of application: Food, chemical industry

Filters for fluid bed dryers

The high-quality processing of the Markert filters for fluid bed dryers guarantees perfect filtration. The welded seam enables us to guarantee little particle loss of your medium. We offer the Markert filters for fluid bed dryers in different sizes, weaving patterns and air permeabilities in an antistatic execution.n an antistatic fabric.

Examples of use: Food, pharma

System: Fluid bed dryers

Areas of application: Food, chemical industry

Filters for dust filtration

In addition to perfect filtration performance and efficiency, Markert dust filters offer easy cake discharge, manufacturing quality for a long service life and high temperature resistance.

Examples of use: Filtration/retention of dust (concrete/lime works)

System: Cartridge filters

Areas of application: Food, chemical industry

Ancillary Products

Steel segments for disc filters

Our disc filter sectors offer high durability with simultaneous very low weight of less than 10 kg. Thanks to their special design, they are the perfect supplement for the Markert filter bags.

Areas of application: Alumina

Plastic support grids for automatic press filters

Depending on the application temperature, we can offer you plastic support grids made of different materials. They offer perfect dewatering performance and high durability.

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Plastic segments for disc filters

Markert plastic segments for disc filters distinguish themselves by their easy handling.

Areas of application: Alumina, Mineral & Mining

Rubber membrane for filter presses and tower presses

Depending on the application conditions, we offer rubber membranes made of different materials.

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Feeding shoe for mining cloths

Use of the Markert feeding shoes makesany additional sealing unnecessary. It allows for simple and easy filter cloth exchange and operation of the filter cloth.

Areas of application: Alumina, Mineral & Mining

Dogpin/Dogcollar

We stocks red & blue dog pins for your plates and high-quality rubber dog collars to keep filter cloths on the dog pins.

Cake Scrapper

16” High grade PP red scrapers in stock.

Pneumatic Air Hammers

For ease of installing gasketed cloths (CGR)

PP Plate Handles

Bolt on replacement handles.

Filter Paper

Various grades of paper available.

EPDM Gasketing

8mm and 9.5mm available for gasketed (CGR) plates.

PP Liner Pipes

Full line of NPT threaded liner pipes in all sizes.

PP Wedges

Used for installing gasketed cloths (CGR)