Service filter technology

Customer-oriented development of fabric

Determination of the filtration properties of fabric

We offer you characterisation of the filter properties of fabric samples in overpressure filtration according to VDI 2762. Our modern laboratory is equipped with professional test equipment by means of which our research and development team is able to analyse the cake weight, the cake height, the residual humidity and much more.

Information on our fabrics

Characteristics of our fabrics

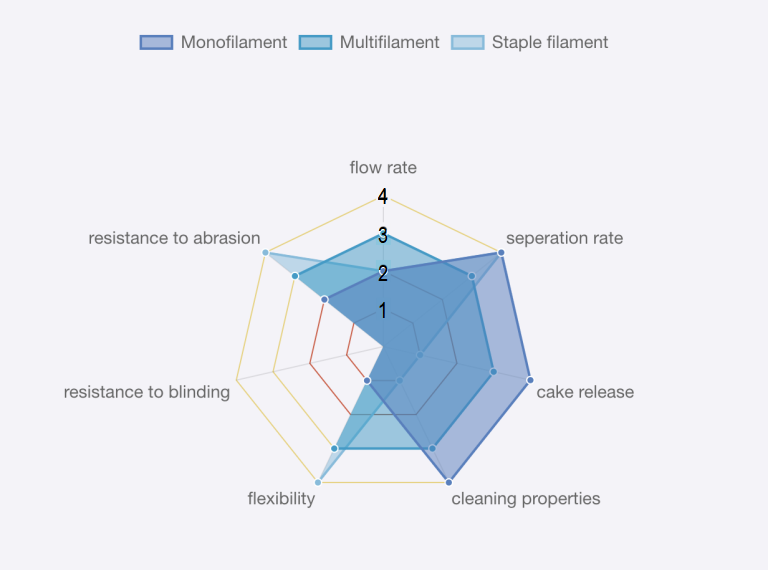

→ Monofilament:

The monofilament yarn is a yarn or thread consisting of only one single filament. It is characterized by excellent resistance to blocking, very easy cleaning, and outstanding ejection of the filter cake, as it hardly sticks to the very smooth monofilament yarns. In addition, monofilament yarns provide superior filtration throughput (filtration speed).

If a high separation efficiency is to be achieved with monofilament yarns, other fabric parameters such as yarn density and weave come more to the fore to make this possible.

→ Multifilament:

The multifilament yarn consists of a series of very fine monofilament threads twisted into a bundle. Usually, multifilament yarns are not measured in mm, but in dtex (most common). This value indicates, in the broadest sense, how many individual yarns make up the bundle. Multifilament fibers have high mechanical stability, very good protection against abrasion, and improved severity compared to monofilaments. However, the increased selectivity is accompanied by an increased risk of particles remaining in the filament and thus reducing its cleanability.

→ Staple filament:

Staple fibers are very similar in appearance to multifilament yarns. However, they do not consist of fibers of the same length but of fibers of different lengths (which are much shorter than the total length of the fiber), which are twisted into a fiber in a non-structured way. The individual fibers do not form a flat picture as in the case of multifilament but protrude irregularly from the fiber. The increased specific surface of the fiber in this way can increase the selectivity. Thus, staple fibers have the best selectivity and the best resistance to blocking. However, this structure also means that staple fibers are difficult to clean, tend to block, and cake release is more difficult due to the large contact surface.

Definition

| 1 | = | poor |

|---|---|---|

| 2 | = | moderate |

| 3 | = | good |

| 4 | = | excellent |

Weaving patterns

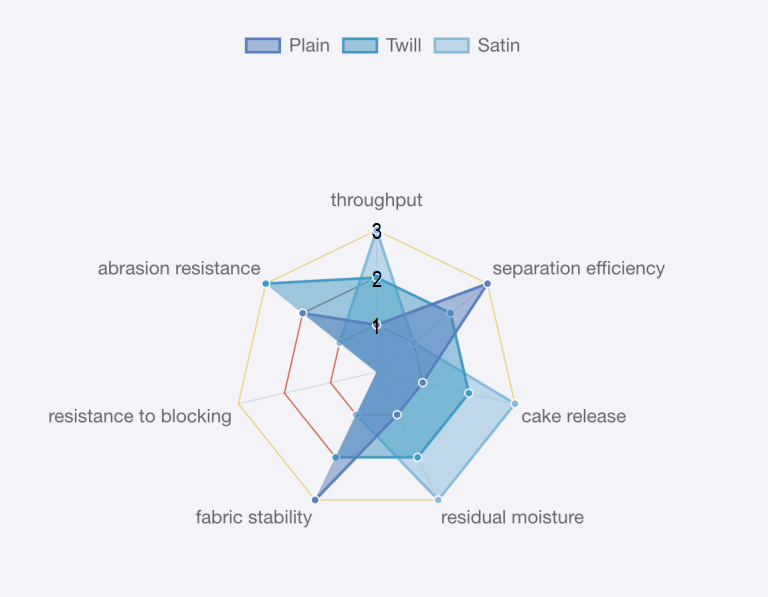

- Plain:

The plain weave is the simplest and oldest weave. Here, a weft thread lies alternately over a warp thread. It is the densest weave and therefore has a high selectivity, good fabric stability and a high resistance to abrasion. However, the cake release is not ideal and, unlike the other weaves, there is an increased risk of blocking.

- Twill:

The twill weave is looser than the plain weave. Here, one warp thread can lie over up to three weft threads. There are many variations of twill weave. Typical for this type of weave is the twill ridge. This type of weave allows more warp threads to be placed on the surface of the fabric. The twill weave is the all-round weave and can do everything well but the other two weaves are better in individual points.

- Satin:

The satin weave is very similar to the twill weave. However, there are no points of contact at the binding points of the warp and weft threads. Here, warp threads can run over up to 7 weft threads. As a result, the weft thread “disappears” from the surface and there are almost exclusively warp threads on the surface. This serves an excellent cake release, a high resistance against blocking and a very high throughput. But the resistance to abrasion and the fabric stability suffer.

Definition

| 1 | = | poor |

|---|---|---|

| 2 | = | moderate |

| 3 | = | good |

| 4 | = | excellent |

Personal consultation

Whether on your premises, in our company or in a contactless manner using digital media: The Markert sales engineers support you in the selection of the perfect filter for your specific applications. This often results in innovative solutions for your processes in the solid/liquid separation area.

We guarantee you products of highest quality the properties of which will convince you in any case.

If you are interested, do not hesitate to contact us.