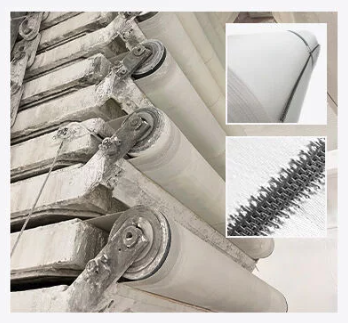

Filter belts

Based on our experience, we offer you high-quality Markert filter belts, seamless up to a width of 4.5 m, and the suitable clipper seam connections. We provide you with the perfect solution for your filtration system used and the process conditions.

We achieve continuous filtration efficiency and long service life. In the following, we present you different solutions.

They can be individually used in most different areas of application on the following systems: Filter belts for belt filters, tower presses, rotary filters, double-belt presses.

Examples of use: Mineral & Mining, alumina, food, chemical industry

Filter belt for phosphoric acid

Benefit from the impressive characteristics of the Markert filter fabric DID 11137. Used in the phosphogypsum filtration area, the process sequence of your system is clearly optimised.

System: Horizontal vacuum belt filters

Examples of use: Phosphogypsum filtration

Filter belt for tower press

Our dimensionally stable belts are available up to a maximum width of 1.7 m and lengths up to 215 m. They ensure reliable straight running with perfect separation effect. Apart from that, they offer excellent cleanability and mechanical resistance. Air permeability is possible within a range from 0.5-270 dm³/dm²*min. The Markert filter belts are pre-stretched to minimise shrinking and stretching.

System: Tower press

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Examples of use: Production of concentrates, calcium phosphate, calcium chloride

Filter belt with rubber mushroom profile

The filter belt features a zipper protected by a sewn-in overlap. This overlap is secured by a second zipper on the filter belt. The rubber profile is equipped with a Clipper seam that has been vulcanized.

System: Rotary drum filters

Areas of application: Mineral & Mining, food

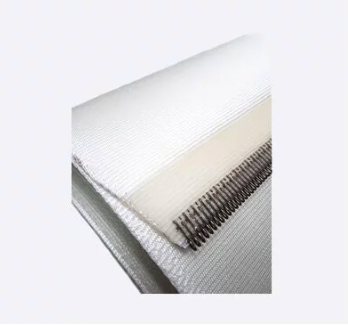

Filter belt with Clipper seam and overlap with rubber mushroom profile

The filter belt features a zipper for quick and easy connection of both junctions. This zipper is protected by a sewn-in overlap, which is secured by a second zipper on the filter belt. The rubber mushroom profile includes a stainless steel Clipper seam that has been vulcanized

System: Belt and rotary filters

Areas of application: Mineral & Mining, food

Filter belt with coated clipper seam

The integrated clipper seam prevents particle loss.

System: Tower press, belt and rotary filters

Areas of application: Mineral & Mining, food, chemical industry

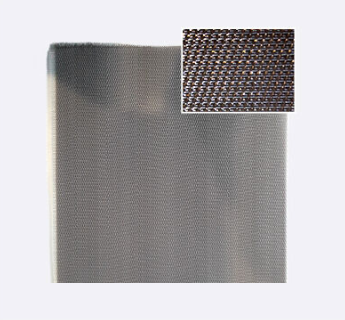

Filter belt made of double-layer fabric with clipper seam

This special binding ensures absolute freedom from folds, good cake separation and excellent dewatering behaviour (maximum width 4.5 m).

System: Belt and rotary filters, vacuum filters

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Examples of use: Production of zinc oxide, jarosite, nickel, zinc and copper concentrate, tailings

Filter belt with seamless overlap

The seamless overlap of the belt allows for a smooth transition at the scraper.

System: Belt and rotary filters

Areas of application: Mineral & Mining, food, chemical industry

Filter belt with overlap and dewatering zone

The dewatering zone prevents collection of solid material between the fabric layers.

System: Belt and rotary filters

Areas of application: Food, chemical industry

Filter belt with flexible plastic pintle wire

Thanks to the integrated plastic wire and the seam, this corrosion-resistant Markert filter belt allows easy assembly. As opposed to steel wires, breaking of the wire is not possible.

System: Belt and rotary filters

Areas of application: Food, chemical industry

Filter belt with especially strengthened side edges

The strengthened side edges promote straight running of the belt and thus prevent fraying of the fabric edges.

System: Belt and rotary filters

Areas of application: Mineral & Mining, food, chemical industry